As an IATF-certified zamak die-casting company, we had the opportunity to collaborate with a renowned company in the automotive industry to produce a zamak part for the armrest of a wide range of cars.

Zamak part for the automotive industry: maximum precision and guaranteed conformity

The goal was to create a high-quality zamak component for the automotive industry that would meet strict precision standards for armrest assembly, with a guarantee of complete conformity, with a view to zero scrap.

In particular, the zamak component for car armrests must respect strict dimensional and geometric tolerances, especially the “true position” and flatness, which are essential to guarantee correct co-moulding and subsequent assembly in the armrest and for its perfect functioning in the vehicle.

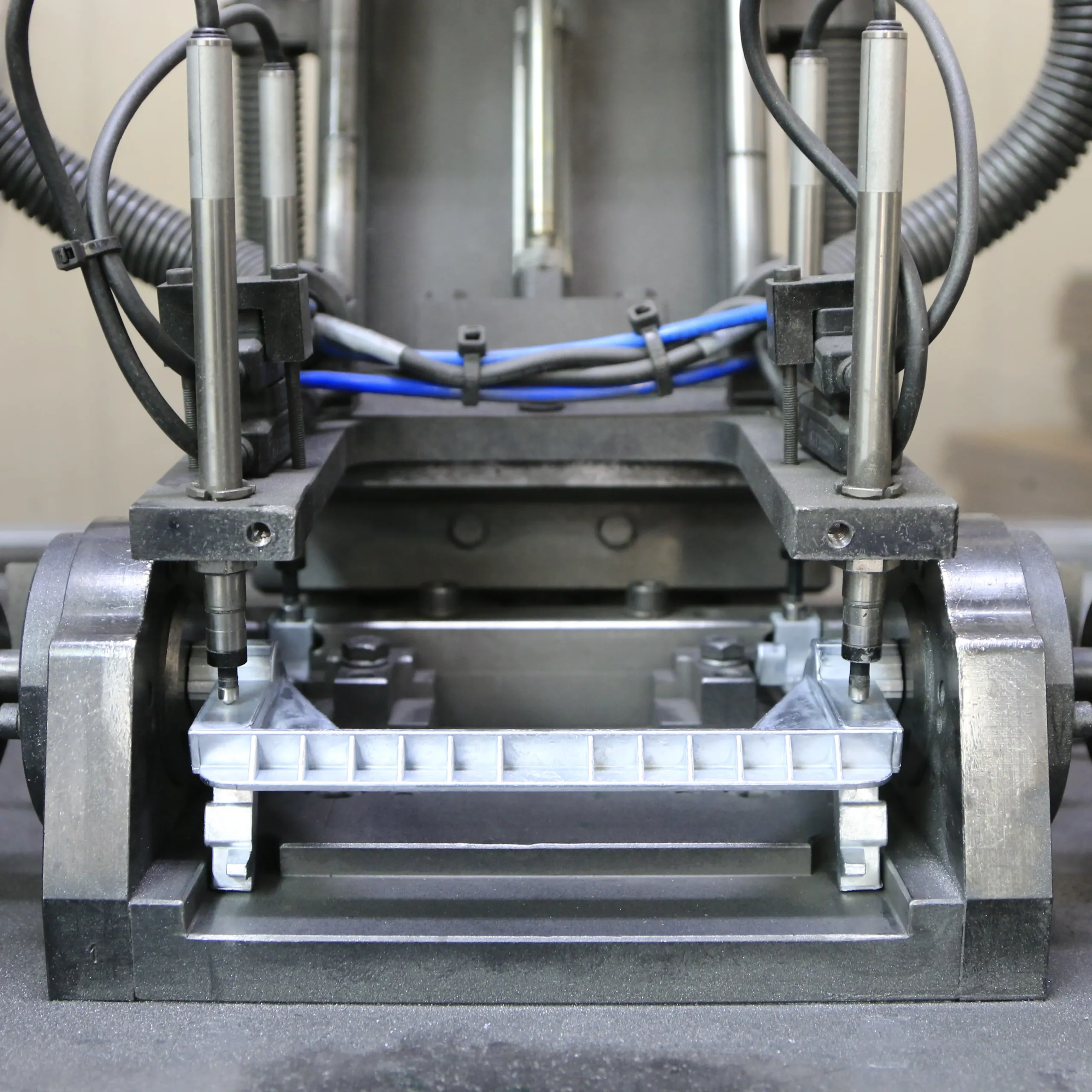

Production of zamak components with 100% off-line control system

To meet this requirement, we have integrated a 100% off-line control system using a semi-automatic machine that measures the dimensions and geometric properties, in particular the flatness and centering, of the zamak automotive component.

Thanks to this advanced control system, carried out after the die casting process and after the surface finishing, and to our experience in the die casting of zamak, we have been able to guarantee a fully compliant production of the component for the car armrest.

This approach allowed us to meet the customer’s needs in terms of reliability, precision and zero scrap, confirming our efforts in the research of advanced solutions for the automotive sector.